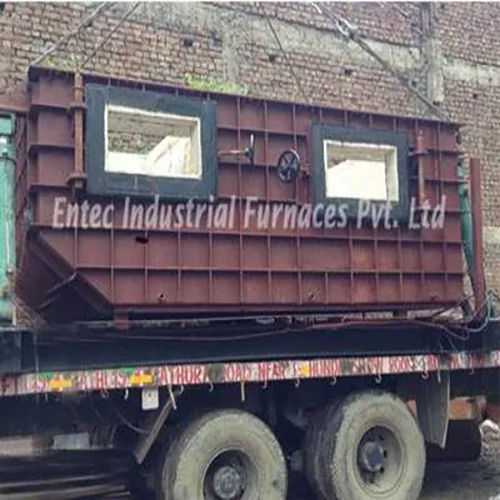

Rotary Hearth Furnaces

Rotary Hearth Furnaces Specification

- Glass Size

- Up to 3000mm diameter

- Rating

- High Performance

- Feature

- Automatic Temperature Control

- Condition

- New

- Usage

- Industrial

- Type

- Furnace

- Size

- Standard

- Power

- 50 kW to 500 kW (configurable)

- Product Type

- Rotary Hearth Furnaces

- Voltage

- 380V / 420V

- Dimensions

- Customized as per requirement

- Weight

- 5 Tons (approximate)

- Application

- Heat Treatment, Forging, Annealing, Hardening, Reheating

- Fuel Type

- Gas / Oil / Electric

- Capacity

- 1 Ton to 10 Tons per batch

- Control Panel

- PLC / HMI based

- Loading Mechanism

- Manual / Automatic

- Cooling System

- Air/Water Cooling

- Emission Compliance

- Meets international standards

- Max Operating Temperature

- 1250°C

- Maintenance Interval

- Semi-annual

- Surface Treatment

- Corrosion Resistant Paint

- Door Type

- Hydraulic / Manual

- Hearth Rotation Speed

- 0.5 to 5 RPM

- Insulation

- Ceramic Fiber / Refractory Brick

- Material

- Heavy Duty Steel

- Ambient Temperature Range

- Up to 50°C

Rotary Hearth Furnaces Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Rotary Hearth Furnaces

Versatile Application & Usage Methods for Rotary Hearth Furnaces

Our Rotary Hearth Furnaces are expertly engineered for a broad spectrum of industrial uses, including heat treatment, forging, annealing, hardening, and reheating. Installation and application methods are highly adaptable, with both manual and automatic loading options to suit your operational needs. Designed for use in industrial sites, these furnaces support continuous and batch usage types. Their robust construction ensures consistent performance in demanding environments, delivering enduring value for any heat-processing line.

Payment, Delivery, and Sample Provisions for Rotary Hearth Furnaces

Enjoy transparent payment terms designed to suit your project's budget and cash flow, reflecting the market value of these world-class furnaces. Our professional transport services guarantee safe, swift delivery, complemented by robust packaging for secure transit. Delivery times are tailored to your requirements, with expedited options available as needed. Interested buyers may request a sample, ensuring confidence in quality and fit before making a full commitment-our commitment is a smooth, satisfactory purchasing experience from order to installation.

FAQ's of Rotary Hearth Furnaces:

Q: How does the automatic temperature control feature benefit my heat treatment process?

A: The automatic temperature control in our Rotary Hearth Furnaces ensures precise, consistent heat levels throughout the process, improving product quality and reducing the need for manual adjustments, which saves time and enhances process reliability.Q: What materials can be processed in these furnaces and what is the maximum batch capacity?

A: These furnaces are engineered for a range of materials and applications, with a batch capacity from 1 ton up to 10 tons, making them ideal for heat treatment, forging, annealing, hardening, and reheating in industrial settings.Q: Where can Rotary Hearth Furnaces be installed for optimal performance?

A: They are best suited for industrial environments with ambient temperatures up to 50C, where stable electrical and fuel connections are available. Custom dimensions ensure they fit into various plant layouts seamlessly.Q: What is the process for ordering and receiving a Rotary Hearth Furnace?

A: Place an order with your requirements, confirm payment terms, and select transport and packaging preferences. Our team will handle production, provide progress updates, and arrange delivery and installation at your location, with lead times customized per project scope.Q: When can I expect delivery after placing my order?

A: Delivery times depend on customization and order volume. Typically, we strive to deliver within a few weeks, using reliable transport services and premium packaging to ensure the furnace arrives safely and ready for installation.Q: What are the maintenance intervals and compliance features of your furnaces?

A: Our Rotary Hearth Furnaces require semi-annual maintenance intervals and meet international emission standards, helping you maintain peak operational efficiency and regulatory compliance with minimal downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Hardening Furnace

Minimum Order Quantity : 1 Unit

Feature : Temperature control, Uniform heating, Digital display

Usage : Other

Size : Customizable as per requirement

Product Type : Hardening Furnace

Type : Furnace

Tower Furnace

Minimum Order Quantity : 1 Unit

Feature : Continuous Operation, Low Maintenance, Uniform Heating

Usage : Melting Furnace

Size : Customizable as per requirement

Product Type : Tower Furnace

Type : Furnace

Electric Holding Furnace

Minimum Order Quantity : 1 Unit

Feature : High Thermal Efficiency, Uniform Heating

Usage : Holding Furnace

Size : Customizable

Product Type : Electric Holding Furnace

Type : Furnace

Heating Furnace

Minimum Order Quantity : 1 Unit

Feature : Energy Efficient, Durable Construction, Fast Heating

Usage : Other, Heating Furnace

Size : Standard/Custom

Product Type : Heating Furnace

Type : Furnace

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS