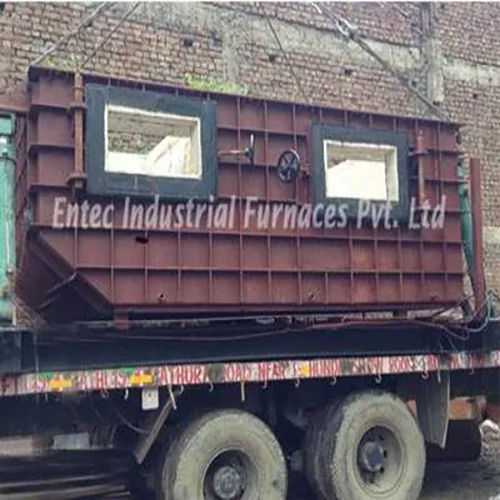

Tower Furnace

Tower Furnace Specification

- Glass Size

- Upto 1m thickness

- Rating

- High Thermal Efficiency

- Feature

- Continuous Operation, Low Maintenance, Uniform Heating

- Condition

- New

- Type

- Furnace

- Usage

- Melting Furnace

- Power

- Gas/Electric

- Voltage

- 220V/380V/440V (based on model)

- Product Type

- Tower Furnace

- Size

- Customizable as per requirement

- Dimensions

- Varies as per capacity

- Weight

- Depends on model; ranges from 2 Tons to 20 Tons

- Application

- Glass Melting, Foundry, Industrial Heating

- Fuel Type

- Natural Gas, LPG, Electricity

- Capacity

- From 2 MT to 20 MT

- Cooling System

- Water/Forced Air

- Body Material

- Mild Steel/SS lined with Refractory

- Chimney Design

- Integrated Flue Gas System

- Insulation

- High-Performance Ceramic Fiber

- Service Life

- 10-15 Years

- Color

- Industrial Grey

- Control System

- Automatic PLC Controller

- Door Type

- Hydraulically Actuated

- Installation

- Onsite Technical Support

- Max Operating Temperature

- Over 1700°C

Tower Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 25 Units Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Tower Furnace

Versatile Usage & Superior Features

The Tower Furnace stands out for its adaptability in demanding industrial environments-be it glass melting, foundry applications, or general industrial heating. It features a hydraulically actuated door, integrated flue gas system, high thermal efficiency, and supports both general and highly specific melting requirements. The continuous operation enables large-scale manufacturing, while the robust construction and uniform heating assure consistent results, making it a preferred solution across a spectrum of industries.

Reliable Supply, Sample Options & Certifications

With a resplendent supply capability tailored to your needs, we offer prompt quotations, secure packing & dispatch services, and swift dispatching timelines. Samples are available for assessment upon request. Our products are manufactured and supplied following stringent quality certifications, ensuring safety and industry compliance. Each Tower Furnace is backed by comprehensive onsite technical support to guarantee seamless performance from delivery to sustained operation.

FAQ's of Tower Furnace:

Q: How is the Tower Furnace installed and what support is provided?

A: Installation is performed onsite by our technical experts, ensuring precise setup and calibration. We offer comprehensive support during and after installation to maximize efficiency and operational safety.Q: What is the typical usage of this Tower Furnace in industry?

A: This furnace is primarily used in glass melting, foundry processes, and various industrial heating applications, supporting continuous operation and large-volume melting requirements.Q: What fuel options and power ratings are available for the Tower Furnace?

A: Our Tower Furnace accommodates natural gas, LPG, and electricity, with voltage ratings of 220V, 380V, or 440V, tailored according to the specific capacity and model requirements.Q: When can I expect the product to be dispatched after placing an order?

A: After you confirm your requirements and receive a quotation, packing and dispatch timelines are promptly shared. Dispatch schedules may vary based on customization and capacity specifications.Q: What certifications and quality assurances come with the Tower Furnace?

A: Each unit is manufactured in compliance with industry standards and certifications. Rigorous quality checks are conducted to ensure dependable performance and safety for all industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Hardening Furnace

Minimum Order Quantity : 1 Unit

Rating : High performance

Application : Heat Treatment, Hardening of metals

Feature : Temperature control, Uniform heating, Digital display

Size : Customizable as per requirement

Forced Air Circulation Tempering Furnace

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Rating : Industrial Grade

Application : Glass Tempering

Feature : Uniform Heat Distribution, Energy Efficient, Digital Controls

Size : Standard

Batch Furnaces

Minimum Order Quantity : 1 Unit

Rating : High thermal efficiency

Application : Industrial heat treatment, glass manufacturing, laboratory use

Feature : Uniform heating, Energy efficient, High insulation, Programmable controls

Size : Customizable as per requirement

Lead Refining Furnace

Minimum Order Quantity : 1 Unit

Rating : High Efficiency

Application : Lead Refining

Feature : Uniform heating, corrosion resistance, durable construction, minimum metal loss

Size : Customized as per requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS