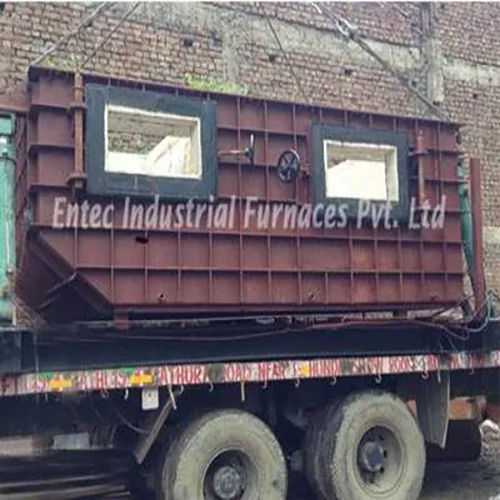

Batch Furnaces

Batch Furnaces Specification

- Glass Size

- Multiple sizes available as per requirement

- Rating

- High thermal efficiency

- Feature

- Uniform heating, Energy efficient, High insulation, Programmable controls

- Condition

- New

- Type

- Furnace

- Usage

- Batch Furnaces

- Power

- Electric/ Gas-fired (as per model)

- Product Type

- Batch Furnaces

- Voltage

- 220V / 380V / 415V (as per customer demand)

- Size

- Customizable as per requirement

- Dimensions

- Varies as per model (customizable)

- Weight

- Depends on model and size

- Application

- Industrial heat treatment, glass manufacturing, laboratory use

- Fuel Type

- Electricity / Gas

- Capacity

- 50 kg to 5000 kg (varies by model)

- Safety Features

- Over-temperature protection, Emergency stop

- Control System

- Digital PID temperature controller

- Ambient Operating Temperature

- 5°C to 45°C

- Chamber Material

- High-grade refractory

- Maximum Working Temperature

- 1100°C - 1300°C

- Insulation Material

- Ceramic fiber blanket

- Automation Grade

- Semi-Automatic / Automatic

- Temperature Range

- Up to 1200°C or higher

- Surface Finish

- Powder Coated / Painted

- Heating Element

- Kanthal A1 / Silicon Carbide / MoSi2

- Door Type

- Front Loading / Top Loading (as per model)

- Cooling System

- Natural / Forced air cooling (optional)

Batch Furnaces Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 7-10 Days

About Batch Furnaces

Versatile Applications & Distinct Advantages

Batch Furnaces are specially designed for varied application media including iron and glass, making them essential for sectors like metallurgy, ceramics, and laboratories. They are particularly suited for plant applications involving melting, heat treatment, and sintering. The main advantage lies in their remarkable operational flexibility, ease of use, and superior thermal efficiency. These features ensure controlled processing, enhanced energy savings, and high-quality results, solidifying their value across different industrial domains.

Efficient Packaging, Swift Delivery & Reliable Exchange Process

Our Batch Furnaces are expertly packaged to guarantee security during outlay and transport services. Each unit is shipped using strong materials and detailed handling protocols, ensuring it reaches you in optimal condition. Delivery time is prompt, and the supply ability is tailored to meet bulk and timetabled requirements. For added assurance, an exchange process is available for eligible models, making your investment reliable, secure, and streamlined.

| Type Of Furnace | Fix |

| Automation Grade | Automatic |

| Country of Origin | Made in India |

| Melting Material | Iron |

| Material Loading Capacity | 500 Kg |

| Power Source | Electric |

| Max Temperature | 500 degree Celsius |

FAQ's of Batch Furnaces:

Q: How does the Batch Furnace operate and what control systems are included?

A: Batch Furnaces operate using advanced digital PID temperature controllers, providing precise and programmable temperature regulation. Automation grades include semi-automatic and automatic models, ensuring user-friendly operation and consistent results.Q: What materials and heating elements are used in these industrial furnaces?

A: The chamber is constructed from high-grade refractory materials and insulated with a ceramic fiber blanket. Heating elements come in options such as Kanthal A1, Silicon Carbide, and MoSi2, offering optimal performance for various industrial processes.Q: Where can Batch Furnaces be installed and what are the available applications?

A: Batch Furnaces are suitable for installation in industrial facilities, laboratories, and plants. They are ideal for heat treatment, glass manufacturing, material testing, and other high-temperature applications.Q: What benefits do Batch Furnaces offer for industrial users?

A: Industrial users benefit from uniform heating, high insulation, energy efficiency, and extensive safety features like over-temperature protection and emergency stop. Customizable options further enhance operational flexibility.Q: When can users expect delivery and how is the furnace packaged?

A: Batch Furnaces are securely packaged for safe transit. Delivery times and supply capabilities are flexible, supporting both standard and custom orders, with efficient transportation and a reliable exchange process for eligible equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Tower Furnace

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V/440V (based on model)

Application : Glass Melting, Foundry, Industrial Heating

Feature : Continuous Operation, Low Maintenance, Uniform Heating

Power : Gas/Electric

Annealing Normalizing Furnace

Minimum Order Quantity : 1 Unit

Voltage : 380V/415V/440V

Application : Annealing and Normalizing of metals

Feature : Uniform temperature distribution, Automated controls, Energy efficient

Power : 20 kW to 500 kW (based on model)

Forced Air Circulation Tempering Furnace

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 380 V / 415 V Volt (v)

Application : Glass Tempering

Feature : Uniform Heat Distribution, Energy Efficient, Digital Controls

Power : 50 kW Watt (w)

Heating Furnace

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V

Application : Metal melting, heat treatment, forging

Feature : Energy Efficient, Durable Construction, Fast Heating

Power : 15100 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS