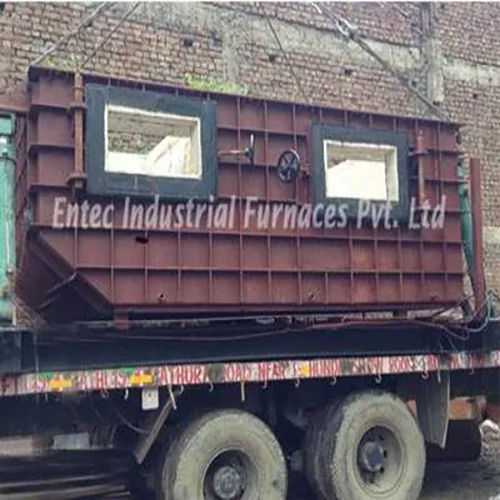

Annealing Normalizing Furnace

Annealing Normalizing Furnace Specification

- Rating

- Heavy Duty Industrial

- Feature

- Uniform temperature distribution, Automated controls, Energy efficient

- Condition

- New

- Type

- Furnace

- Usage

- Normalizing Furnace

- Power

- 20 kW to 500 kW (based on model)

- Product Type

- Annealing Normalizing Furnace

- Voltage

- 380V/415V/440V

- Size

- Customizable as per requirement

- Dimensions

- Depends on selected model and application

- Weight

- Varies by customization; typically 2000 Kg to 25000 Kg

- Application

- Annealing and Normalizing of metals

- Fuel Type

- Electric / Gas / Oil Fired

- Capacity

- 300 Kg to 10 Tons per batch

- Insulation Material

- High-alumina ceramic fiber

- Heating Element

- MoSi2 / Kanthal / Silicon Carbide

- Chamber Type

- Single/Multiple Chambers

- Temperature Range

- Up to 1200°C

- Installation

- Onsite assistance available

- Material of Construction

- Mild steel body with refractory lining

- Safety Features

- Over-temperature protection, emergency shut-off

- Atmosphere Control

- Air, Nitrogen, Inert available on request

- Cooling System

- Natural/Forced air or water cooling available

- Control System

- PLC based automation, digital temperature controller

- Door Type

- Manual or motorized, side opening or top lifting options

Annealing Normalizing Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Annealing Normalizing Furnace

Versatile Furnace for Industrial Metal Processing

The Annealing Normalizing Furnace is widely used for the controlled heating and cooling of metals to enhance structural properties. Its main usage lies in industrial annealing and normalizing processes, designed to streamline metallurgical operations for steel, alloy, and ferrous components. This crackerjack machine is suited for heavy-duty, batch-type applications, offering customizable chamber sizes and cooling methods. Usage types include normalization, annealing, and heat treatment, optimized for supreme efficiency in manufacturing facilities and foundries.

Domestic Market Reach and Seamless Delivery

Catering to India's vast industrial sector, our Annealing Normalizing Furnace is shipped with secure outlay and robust packaging to ensure safe arrival nationwide. Stock is ready for both large-scale and specialized requirements, and sample demonstration units are available on request prior to bulk purchase. Packaging details emphasize durability for heavy shipments, and our technical team ensures every installation meets site-specific demands, providing champions of industry a seamless procurement and setup experience.

FAQ's of Annealing Normalizing Furnace:

Q: How does the Annealing Normalizing Furnace benefit industrial metal processing?

A: It delivers uniform temperature distribution and precise automated control, ensuring consistent material properties while optimizing process efficiency, energy usage, and product quality.Q: What materials and fuels are compatible with this furnace?

A: The furnace accommodates multiple heating elements (MoSi2, Kanthal, Silicon Carbide) and supports electric, gas, or oil-fired operation, making it suitable for various metals like steel, alloys, and ferrous components.Q: When should I select air, nitrogen, or inert atmosphere control?

A: Atmosphere control choice depends on your metallurgical requirements; use air for standard processes, nitrogen or inert gases to prevent oxidation in sensitive alloys or specialty treatments.Q: Where can the Annealing Normalizing Furnace be installed?

A: Installation is available onsite across India, ensuring customized setup and operational assistance at your manufacturing location by expert technicians.Q: What is the capacity range and customization available?

A: The furnace handles batches from 300 kg up to 10 tons, with customizable size, power requirements (20 kW-500 kW), voltage (380V/415V/440V), and chamber designs tailored to your operational needs.Q: How does the safety system work in the furnace?

A: Equipped with over-temperature protection and an emergency shut-off, the system ensures safe operation, protecting personnel and product integrity during every use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Hardening Furnace

Minimum Order Quantity : 1 Unit

Voltage : 380V 440V, 3 Phase

Product Type : Hardening Furnace

Size : Customizable as per requirement

Condition : New

Dimensions : As per design specifications

Tower Furnace

Minimum Order Quantity : 1 Unit

Voltage : 220V/380V/440V (based on model)

Product Type : Tower Furnace

Size : Customizable as per requirement

Condition : New

Dimensions : Varies as per capacity

Zinc Melting Furnace

Minimum Order Quantity : 1 Unit

Voltage : 415 V AC

Product Type : Zinc Melting Furnace

Size : Customized

Condition : New

Dimensions : As per requirement

Batch Furnaces

Minimum Order Quantity : 1 Unit

Voltage : 220V / 380V / 415V (as per customer demand)

Product Type : Batch Furnaces

Size : Customizable as per requirement

Condition : New

Dimensions : Varies as per model (customizable)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS