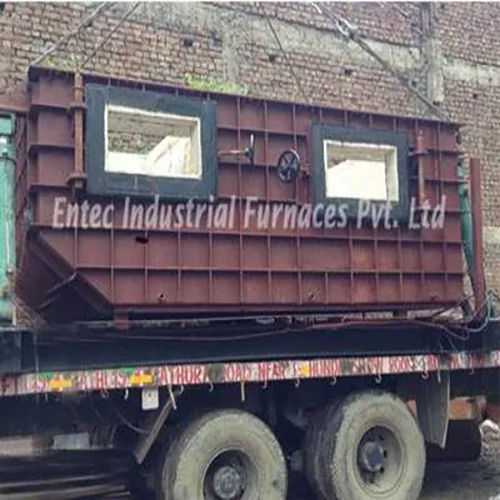

Tilting Furnace

MOQ : 1 Unit

Tilting Furnace Specification

- Feature

- Tiltable Design, Energy Efficient, Robust Construction, Easy Operation

- Rating

- High Performance

- Condition

- New

- Type

- Furnace

- Usage

- Tilting Furnace

- Power

- Electric, Oil or Gas Fired (as per model)

- Product Type

- Tilting Furnace

- Voltage

- 380V / 415V (Three Phase)

- Size

- Customizable or Standard (as per requirement)

- Dimensions

- As per design & capacity (customizable)

- Weight

- Varies as per capacity and specification

- Application

- Metal Melting, Foundry, Casting

- Fuel Type

- Electric / Oil / Gas

- Capacity

- 500 kg to 5 Tons (varies by model)

- Insulation Material

- High Alumina Brick & Ceramic Wool

- Control System

- Digital Temperature Controller with PID

- Applicable Metals

- Aluminium, Brass, Bronze, Copper, Zinc

- Furnace Lid

- Heavy Duty Hinged or Removable Lid

- Cooling System

- Water Cooled Panel (optional for large capacities)

- Tilting Mechanism

- Manual / Motorized / Hydraulic

- Surface Finish

- Painted / Powder Coated

- Chamber Shape

- Rectangular / Circular

- Melting Temperature

- Up to 1700°C

- Automation

- Optional PLC Based Controls

- Combustion System

- Efficient High-Speed Burners (for oil/gas models)

- Material of Construction

- Mild Steel / Stainless Steel (as per request)

- Safety Features

- Over-temperature Protection, Emergency Stop System

Tilting Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 50 Units Per Month

- Delivery Time

- 7-10 Week

- Main Domestic Market

- All India

About Tilting Furnace

Discover a hot-selling Tilting Furnace, renowned for its meritorious design and radiant performance. Crafted from elite mild steel or stainless steel by request, it supports melting temperatures up to 1700C. This hot deal includes a manual, motorized, or hydraulic tilting mechanism, highlighted with a digital PID controller for precision. Enhanced safety features, such as over-temperature protection and emergency stop system, ensure reliable usage. Flexible chamber shapes and customizable sizes cater to diverse industrial requirements, making it ideal for aluminium, brass, bronze, copper, and zinc. Energy efficient, robust, and easy to operate, this furnace is your ultimate foundry solution.

Wide-Ranging Application Areas for the Tilting Furnace

The Tilting Furnace serves crucial roles in a variety of industries, particularly metal melting, foundry operations, and casting processes. Specifically designed for processing aluminium, brass, bronze, copper, and zinc, it is suitable for both small batch and large-scale production. Its versatile construction supports robust industrial usage and ensures consistent results across customizable or standard capacities. Whether you are in a manufacturing plant or a specialized casting facility, this high-performance furnace offers seamless adaptability.

FOB Port, Payment Terms & Sample Availability

All tilting furnaces are offered with a convenient FOB port handover, ensuring secure drop-off points for domestic and international customers. Shipped goods are thoroughly inspected prior to dispatch. Flexible payment terms cater to various client requirements, from upfront arrangements to installment-based options. For evaluation, sample furnaces can be made available upon request, supporting informed investment decisions and smooth coordination throughout the purchasing process.

Wide-Ranging Application Areas for the Tilting Furnace

The Tilting Furnace serves crucial roles in a variety of industries, particularly metal melting, foundry operations, and casting processes. Specifically designed for processing aluminium, brass, bronze, copper, and zinc, it is suitable for both small batch and large-scale production. Its versatile construction supports robust industrial usage and ensures consistent results across customizable or standard capacities. Whether you are in a manufacturing plant or a specialized casting facility, this high-performance furnace offers seamless adaptability.

FOB Port, Payment Terms & Sample Availability

All tilting furnaces are offered with a convenient FOB port handover, ensuring secure drop-off points for domestic and international customers. Shipped goods are thoroughly inspected prior to dispatch. Flexible payment terms cater to various client requirements, from upfront arrangements to installment-based options. For evaluation, sample furnaces can be made available upon request, supporting informed investment decisions and smooth coordination throughout the purchasing process.

FAQ's of Tilting Furnace:

Q: How does the tilting mechanism enhance operational efficiency?

A: The tilting mechanism, available in manual, motorized, or hydraulic options, enables quick and precise pouring of molten metal, reducing operator effort and improving work safety. This feature streamlines batch changes and minimizes downtime.Q: What materials can be melted using this tilting furnace?

A: This furnace is designed to melt a range of metals, including aluminium, brass, bronze, copper, and zinc. Its adaptable construction meets diverse industrial applications within foundries and casting facilities.Q: What are the available control and safety features?

A: Every unit is equipped with a digital PID temperature controller for accuracy, over-temperature protection, and an emergency stop system to guarantee safety during operation.Q: Where can the tilting furnace be employed most effectively?

A: It is best suited for use in metalworking, foundries, and industrial casting units where reliable metal melting and precise control are critical factors in daily operations.Q: What is the process for ordering a customized unit?

A: Customers can specify material, size, chamber shape, and other features at the time of order. The manufacturer then supplies a unit built to exact requirements for optimal performance and application.Q: What are the main benefits of using a PLC-based automation system?

A: PLC-based controls (optional) offer enhanced automation, user-friendly interfaces, and accuracy, reducing manual intervention and improving productivity for large-scale or continuous operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Industrial Furnace Category

Tower Furnace

Minimum Order Quantity : 1 Unit

Rating : High Thermal Efficiency

Condition : New

Usage : Melting Furnace

Product Type : Tower Furnace

Forced Air Circulation Tempering Furnace

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Rating : Industrial Grade

Condition : New

Usage : Other, Tempering Furnace

Product Type : Forced Air Circulation Tempering Furnace

Melting Cum Holding Furnace

Minimum Order Quantity : 1 Unit

Rating : High Efficiency

Condition : New

Usage : Holding Furnace

Product Type : Melting Cum Holding Furnace

Zinc Melting Furnace

Minimum Order Quantity : 1 Unit

Rating : High Efficiency

Condition : New

Usage : Melting Furnace

Product Type : Zinc Melting Furnace

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS