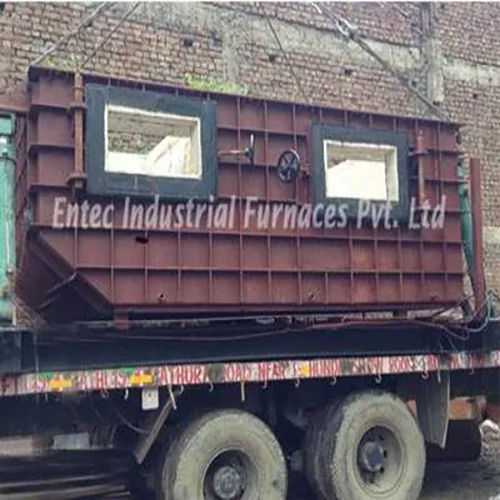

Stress Relieving Furnace

Stress Relieving Furnace Specification

- Feature

- Uniform temperature distribution, energy efficient, PLC control, high thermal efficiency

- Rating

- Industrial Grade

- Condition

- New

- Type

- Furnace

- Usage

- Relieving Furnace

- Power

- Depends on Model (typically 15-200 kW)

- Product Type

- Stress Relieving Furnace

- Voltage

- 415 V

- Size

- Customizable

- Dimensions

- As per client requirement

- Weight

- Varies with model

- Application

- Stress relieving and annealing of fabricated metal components

- Fuel Type

- Electric / Gas / Oil Fired

- Capacity

- 500 kg to 50,000 kg per batch

- Safety Features

- Overtemperature protection, door interlock system, alarms

- Insulation Type

- High density ceramic fiber / refractory bricks

- Material of Construction

- Mild Steel / Stainless Steel

- Heating Method

- Electric or Fuel-fired heating elements

- Controller

- Digital PID / PLC Based Controller with Data Logger

- Temperature Range

- Up to 1100°C

- Chamber Type

- Horizontal / Vertical / Bogie hearth

- Door Mechanism

- Manually or hydraulically operated

Stress Relieving Furnace Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Stress Relieving Furnace

Versatile Machine For Industrial Stress Relief

Our Stress Relieving Furnace excels in commercial environments for heat treating metal components in sectors such as automotive, heavy engineering, and fabrication. Its key features include precise PLC-based control, excellent insulation with ceramic fiber or refractory lining, and energy-efficient operations. Designed for applications such as stress relief and annealing, it accommodates various batch sizes and chamber types, making it an indispensable asset for customized metal processing needs in any renowned industrial setup.

Global Export Excellence and Trusted Certifications

We offer the Stress Relieving Furnace to soaring international markets through meticulously managed logistics solutions. Each unit is securely packaged in wooden crates or robust steel frames for safe transportation. Our asking price reflects advanced technology and reliable quality, with special promotions and offers available for bulk or advance purchases. The furnace is certified by leading industry authorities, ensuring compliance and customer peace of mind across all major export destinations for renowned application areas.

FAQ's of Stress Relieving Furnace:

Q: How does the Stress Relieving Furnace aid in relieving stress from metal components?

A: The furnace employs controlled heating and cooling cycles at temperatures up to 1100C, which helps in reducing residual stresses in fabricated metal components, thus enhancing their durability and performance.Q: What are the main commercial usages of this furnace?

A: It is primarily used in automotive, heavy machinery, and fabrication facilities for processes like stress relieving and annealing of welded structures or metal parts, ensuring structural stability and longevity.Q: When should I opt for electric versus fuel-fired heating elements?

A: Electric heating is ideal for precise temperature control and cleaner operations, whereas fuel-fired options (gas or oil) are preferred for larger batch sizes where operational costs and energy input are optimized.Q: Where can the furnace be installed?

A: The furnace is designed for flexible installation at any industrial facility, and our team provides full support and customization to fit your available space and processing requirements.Q: What is the process for advance purchase or promotional offers?

A: You may contact our sales team for information on current promotions and advance purchase deals. We provide detailed quotations and can accommodate logistics planning to align with your project schedule.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Furnace Category

Tower Furnace

Minimum Order Quantity : 1 Unit

Size : Customizable as per requirement

Feature : Continuous Operation, Low Maintenance, Uniform Heating

Condition : New

Type : Furnace

Heat Treatment Furnace

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Customizable as per requirement

Feature : High Efficiency, Temperature Uniformity, Digital Controls, Robust Construction

Condition : New

Type : Furnace

Annealing Normalizing Furnace

Minimum Order Quantity : 1 Unit

Size : Customizable as per requirement

Feature : Uniform temperature distribution, Automated controls, Energy efficient

Condition : New

Type : Furnace

Heat Treatment Furnaces

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Customizable as per requirements

Feature : Robust construction, Uniform heating, Digital temperature control, Energy Efficient

Condition : New

Type : Furnace

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free